In the energy industry, copper is essential, particularly for EPC (Engineering, Procurement, and Construction) projects. It is essential in many applications, ranging from electrical wiring to renewable energy systems, due to its exceptional electrical conductivity, malleability, and durability. However, changes in copper prices can have a big impact on EPC projects, changing the budget, schedule, and viability of the project as a whole.

Prices for copper have recently skyrocketed, rising by 23% between April 2024 and June 2024. Let’s examine the effects of these variations on EPC projects in the energy industry.

The Role of Copper in EPC Projects

Copper is a critical material in the energy sector for several reasons:

Electrical Wiring and Cables: Copper’s high conductivity makes it the preferred choice for electrical wiring and cables in power generation, transmission, and distribution.

Renewable Energy Systems: Copper is used extensively in solar panels, wind turbines, and other renewable energy technologies.

Transformers and Motors: Copper is a key component in transformers, motors, and other electrical equipment due to its efficiency in conducting electricity.

Construction Materials: In addition to electrical applications, copper is also used in various construction materials for its durability and resistance to corrosion.

Given its widespread use, fluctuations in copper prices can have a ripple effect across the entire energy sector, particularly in EPC projects.

Recent Trends in Copper Prices

In the past two months, from April 2024 to June 2024, copper prices have increased by 23%. This sharp rise can be attributed to several factors:

Supply Chain Disruptions: Ongoing supply chain issues, including disruptions caused by geopolitical tensions and logistical challenges, have constrained copper supply.

Increased Demand: The global push for renewable energy and the electrification of various sectors have driven up the demand for copper.

Speculative Trading: Market speculation and trading activities also contribute to price volatility.

The impact of this price increase is multifaceted, affecting various aspects of EPC projects.

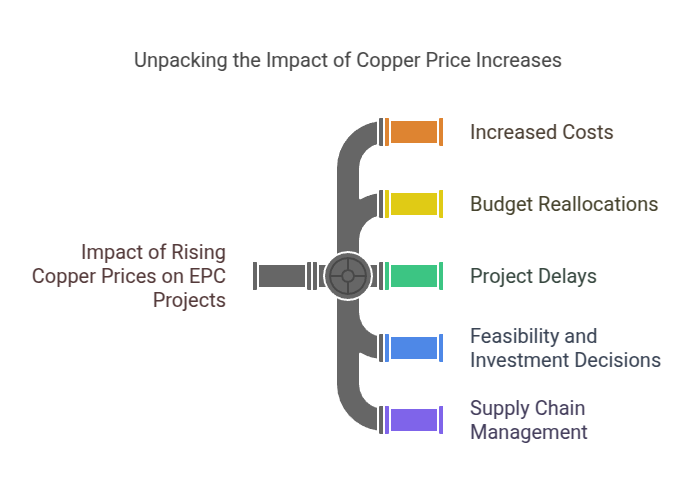

Impact on EPC Projects

1. Increased Costs

One of the most direct impacts of rising copper prices is the increase in overall project costs. Specifically, the balance of system (BOS) costs for renewable energy projects has increased by almost 3.5%. BOS costs encompass all components of a renewable energy system except for the photovoltaic (PV) panels themselves. These include wiring, inverters, racking systems, and other electrical components, all of which rely heavily on copper.

2. Budget Reallocations

EPC contractors can need to reallocate budgets to accommodate higher material costs. This can result in the need to cut costs in other areas, potentially affecting the quality and scope of the project. For instance, contractors might opt for cheaper alternatives or reduce the scale of certain components, which could impact the project’s overall efficiency and lifespan.

3. Project Delays

Higher copper prices can lead to delays in project timelines. EPC contractors may need additional time to source copper at reasonable prices, renegotiate contracts, or adjust project designs to mitigate cost increases. Delays can have cascading effects, including missed deadlines, extended financing costs, and potential penalties for late delivery.

4. Feasibility and Investment Decisions

Fluctuating copper prices can affect the feasibility of new EPC projects and investment decisions. Higher costs can deter investors or lead to the postponement of projects. For renewable energy projects, in particular, increased costs can impact the levelized cost of energy (LCOE), making projects less competitive compared to traditional energy sources.

5. Supply Chain Management

EPC contractors need to manage their supply chains more effectively to cope with price volatility. This might involve entering into long-term contracts with copper suppliers, diversifying supply sources, or investing in inventory to hedge against future price increases.

Strategies to Mitigate Impact

1. Long-term Contracts

EPC contractors can enter into long-term contracts with copper suppliers to lock in prices and ensure a steady supply of materials. This approach can provide more predictable costs and reduce the risk of price fluctuations.

2. Material Substitution

Where feasible, contractors can explore alternative materials that can substitute for copper. For example, aluminum is sometimes used as a substitute for copper in electrical applications, although it may require design adjustments due to its different properties.

3. Technological Innovations

Investing in technological innovations can help reduce reliance on copper. For instance, advancements in power electronics and energy storage technologies can reduce the copper content required in renewable energy systems.

4. Efficient Project Management

Implementing efficient renewable energy projects management practices can help mitigate the impact of price fluctuations. This includes rigorous cost control, efficient procurement processes, and effective risk management strategies.

5. Government Policies and Incentives

Government policies and incentives can play a crucial role in mitigating the impact of rising copper prices. Subsidies, tax incentives, and support for research and development in alternative materials and technologies can help offset increased costs and promote the continued growth of the energy sector.

Future Outlook

Well, The future of copper prices and their impact on EPC projects in the energy sector will depend on several factors, including global economic conditions, technological advancements, and the regulatory environment.

HARTEK is Prepared!

Despite the challenges posed by fluctuating copper prices, companies like Hartek Group are well-prepared to tackle these situations. Hartek Group has implemented strategic measures to mitigate the impact of rising copper costs. By adopting long-term contracts, exploring material substitution, and optimizing project management, they have built resilience against price volatility.

Hartek Group remains committed to delivering high-quality EPC projects, regardless of market fluctuations. Their proactive approach and preparedness ensure that they can navigate these challenges effectively. As the global energy sector continues to evolve, Hartek Group’s adaptability and resilience will be crucial for the successful execution of EPC projects.

With a positive outlook and strategic planning, companies like Hartek Group are ready to face any situation, ensuring continued progress and innovation in the energy sector.

Frequently Asked Questions:

-

Why are copper prices rising in 2024?

Copper prices have surged due to supply chain disruptions, increased demand from renewable energy projects, and speculative market trading. -

How do rising copper prices impact EPC projects?

Higher copper costs increase project expenses, cause budget reallocations, lead to delays, and affect investment decisions in the energy sector. -

What strategies can EPC contractors use to manage copper price fluctuations?

Contractors can enter long-term contracts, explore material alternatives like aluminum, adopt technological innovations, and optimize supply chains. -

How do rising copper prices affect renewable energy projects?

Increased copper costs raise the Balance of System (BOS) expenses, impacting the overall feasibility and competitiveness of renewable energy projects. -

How is Hartek Group managing rising copper prices?

Hartek Group mitigates price volatility through long-term supplier contracts, material substitution, efficient project management, and strategic planning.

Share:

Explore More

Keep up-to-date with the most trending news stories that are shaping the world today.