It is not just major transformers or heavy switchgear that constitute the backbone of a stable and efficient power infrastructure, but the invisible intelligence that ensures safety, synchronization, and operation. This intelligence is provided by a Control Relay Panel (CRP), a vital part of any modern electrical substation.

The need for reliable and advanced control and relay systems has grown immensely in parallel with the process of India’s electrification network’s reinforcement and the transmission infrastructure spreading across the districts. Whether it is a control and relay panel in a substation, a 132 kV control relay panel, or a 220 kV control relay panel, these solutions form the nerve centre of grid protection.

Hartek, one of India’s leading engineering, grid-synchronisation, and substation solution providers, continues to empower the country’s electrical ecosystem with high-quality, technologically advanced relay and control panels that deliver reliability, safety, and precision.

India’s Power Infrastructure Expansion: A Stronger Case for Control Relay Panels

India’s power transmission network has been growing rapidly over the last few years, with a substantial increase in the kilometers of new transmission lines and the number of substations on an annual basis. Rising industrial demand, urbanization, and renewable energy generation have led to the need for substations capable of handling higher electrical loads while ensuring the stability of the network.

In such a situation, the Control Relay Panel is the brain of the substation, where all the surveillance and protection activities are carried out. It is the main instrument by which the entire substation can be made safer and more reliable in case of fault situations.

If we consider the increasing complexity of power grids due to the incorporation of renewables, digitalization, and higher voltage systems, then we can understand the significance of an advanced CRP even more.

What Makes a Control Relay Panel the Heart of a Substation?

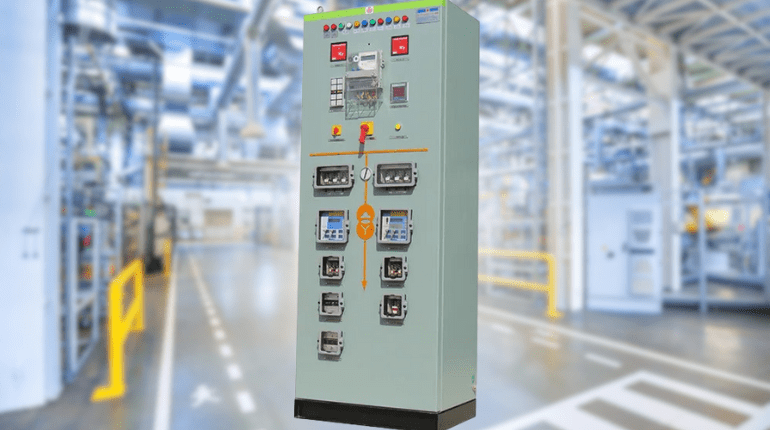

A Control Relay Panel is far beyond the simple metal case with output and input wires and relays. It is the “decision-maker” that continuously scrutinizes the situation, recognizes abnormal operations, and initiates the required protective actions.

Some of the functions that a reliable CRP performs are:

- Exact system monitoring using meters, indicators, SCADA inputs, and protection relays

- Detection of the fault and cutting off the affected section to stop the spread of blackouts

- Interaction among different protection devices

- Operation of breakers and isolators in a safe manner

- Uninterrupted communication with SCADA and remote-control systems

In the absence of a trustworthy control relay panel, a high-tech substation just might be vulnerable to failures, are unstable, and will have to stop for quite a long time.

Why Every Substation Distribution, Transmission, or Renewable, Depends on a Reliable CRP

1. Protection Against Electrical Faults

Short circuits, overcurrent, earth faults, and insulation failures are the most common types of faults that can happen in a power network. A Control Relay Panel is the one which detects those problems immediately and separates the infected area.

By doing this, it stops the following:

- Destruction of the devices

- Fire hazards

- Blackouts

- Instability of the grid

At high-voltage systems, even a delay of a few milliseconds can bring about extensive destruction, thus fast and intelligent relay action is absolutely necessary.

2. Operational Efficiency and Control

With the help of a CRP the operator has control over several functions in the substation through a single interface. Today’s CRPs come with:

- SCADA integration

- Remote operation

- Advanced numerical relays

- Real-time data logging

Such an arrangement is an efficient way for running the operations and a great decision-making tool.

3. Seamless Integration of Renewables

India is experiencing an exponential growth in solar and wind energy and that is why substations need to be able to manage variable power flows. Control Relay Panels facilitate a smooth connection to the grid and allow renewable energy sources to meet the grid’s requirements by:

- Adjusting for variations

- Reporting power quality

- Enabling the automated switching and protection operations

4. Standardisation and Safety

High-voltage substations, especially 132 kV control relay panel and 220 kV control relay panel configurations, must comply with strict safety norms. CRPs ensure all operations follow the correct logic and lockout procedures.

What is more, this safety measures feature protects both the apparatus and the workers.

Modern Substations Use Different Control Relay Panels

1. Feeder Protection Panels

They are used for the feeder lines of transmission and distribution.

2. Transformer Protection Panels

They provide differential, overcurrent, and Buchholz protection.

3. Busbar Protection Panels

They stabilize the main power distribution system.

4. DG/Generator Relay Panels

They are the most common in industrial plants and captive power systems.

5. Numerical Relay Panels

They are armed with microprocessor-based protection relays for advanced accuracy and automation.

India’s Growing Demand for 132 kV and 220 kV Control Relay Panels

The transition of India to a more reliable and smarter power network raises the need for substations working at higher voltages. This, in turn, causes the demand for the following to increase:

1. 132 kV Control Relay Panel

It is the most common use in state transmission utilities and industrial substations. Perfect for:

- Medium-scale transmission

- Renewable grid integration

- Industrial clusters and SEZs

2. 220 kV Control Relay Panel

The main requirement for the transmission corridors with high capacity. These panels provide:

- Highly sensitive numerical relay protection

- Quick clearing of faults

- SCADA-enabled automation

The accuracy as well as the dependability of CRPs at these voltage levels are the main factors that determine grid stability and uptime.

HARTEK’s Specialization in Delivering Trustworthy Control Relay Panels

Hartek has made a name for itself as one of the most reliable Indian companies in the field of power infrastructure engineering. The company along with its EPC, substations up to 765 kV, and more than 10 GW of grid connectivity experience for decades has acquired a profound technical knowledge which it now brings to CRP manufacturing.

Hartek’s CRPs Are Distinguished By:

- Most up-to-date numerical relays from the top global brands

- Highly accurate wiring and quality control

- Tailored designs according to substation needs

- Good performance and a long operating duration

- Excellent SCADA and communication integration

- Following IEC and IS standards

Hartek’s CRPs are a safety, automation, and operational excellence upgrade that can be found in small distribution substations and large interstate transmission systems alike.

The Future: Digital and Intelligent CRPs

Digitalization is the future of substations, and so CRPs are changing accordingly as well.

The coming generation of control and relay panels will be equipped with:

- Communication based on IEC 61850

- IoT sensors working in real-time

- Fully digital protection schemes

- AI-supported fault analysis

- Less wiring due to process bus technology

Such features will help substations to become more resilient, efficient, and self-correcting, which is in line with India’s move towards smart grids.

Conclusion: A Control Relay Panel with Reliable Operations Is a Must for Every Substation

The existence of a robust Control Relay Panel is what safety, stability, and operational reliability hinge on in every substation, be it a conventional one or a renewable one. The central intelligence that it is, a CRP stops faults from happening, helps in utilizing the resources more efficiently, and ensures that the flow of electricity goes smoothly without any interruptions.

With the country going through such an unprecedented scale of power infrastructure, the demand for reliable CRPs, whether 132 kV, 220 kV, or customized, will not be exhausted.

With the help of their strong engineering capabilities and profound domain expertise, companies like Hartek Group are the ones who play the pivotal role in equipping Indian substations with the most efficient control and protection systems, thus enabling uninterrupted power supply to the homes, industries, and the nation’s fast-developing economy.

Frequently Asked Questions (FAQ)

1. What does a Control Relay Panel do in a substation?

By detecting faults and isolating the faulty sections, a Control Relay Panel monitors, controls, and protects the electrical equipment.

2. What distinguishes a 132 kV Control Relay Panel from a 220 kV one?

132 kV CRP is the device that is used in the case of transmission substation of medium-voltage, whereas the function of 220 kV CRP is to work with high-capacity transmission lines and also demands more advanced protection schemes.

3. For a renewable energy substation, why is a CRP necessary?

Since renewable energy sources produce power that fluctuates, CRPs are instrumental in grid stability by controlling the variations, protecting the equipment, and ensuring grid code compliance.

4. In what ways does a numerical relay make a CRP more efficient?

A numerical relay can provide protection faster and with more accuracy, give detailed fault analysis, reduce the wiring needed, and allow for digital communication with SCADA systems.

5. What are the reasons for choosing Hartek for Control Relay Panels?

Hartek offers CRPs that are of high quality, customized and compliant with the standards. They are constructed with cutting-edge relays, dependable design, and robust integration capabilities for all voltage levels.