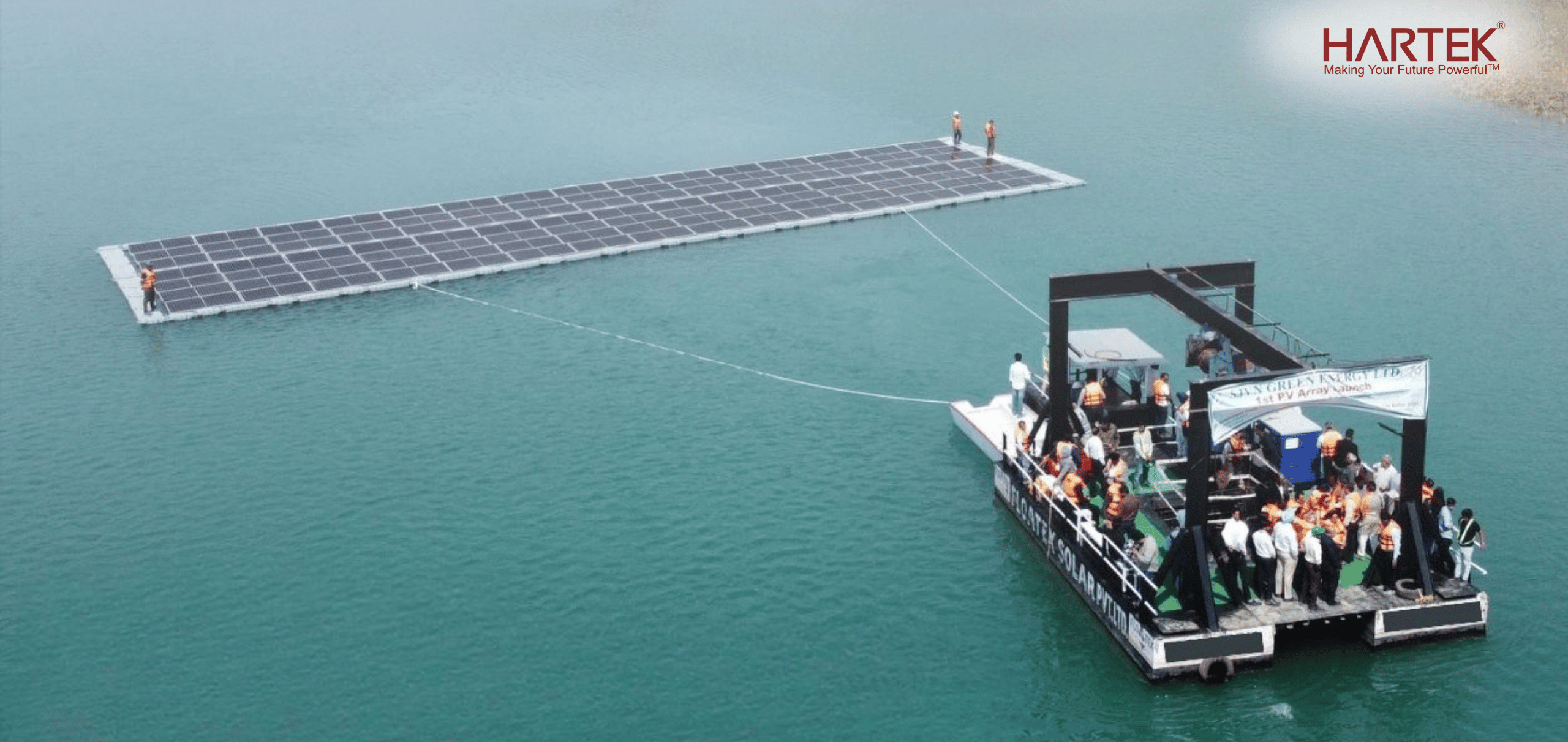

The Hartek Group has once again showcased its commitment to breaking barriers and making waves in the renewable energy sector with the launch of the PV Module Array of the monumental 22MW Nangal Floating Solar Project. This ground-breaking project, situated on the Nangal reservoir, is not just about numbers; it represents a significant stride towards decarbonisation, net zero-emission, and India’s power transition.

Setting New Standards for Sustainable Energy Solutions

With 105 modules securely placed and tied down using the state-of-the-art Mooring & Anchoring System, the Nangal Floating Project is a game-changer in India’s Northern Region. The project’s significance extends beyond its capacity; it symbolises the Hartek Group’s dedication to making a real difference in the country’s energy landscape.

Leading India’s Clean Energy Revolution

The foundation stone of the Nangal Floating Solar Project was laid by the Hon’ble Prime Minister Shri Narendra Modi, underscoring the Hartek Group’s position at the forefront of India’s clean energy revolution. The project has garnered recognition and support from Smt. Geeta Kapur, Chairman & Managing Director of SJVN Limited, who was present at the launch and lauded the efforts of Hartek Group in assisting SJVN to become India’s largest power producer. The presence and words of motivation from industry leaders such as Sh. Akhileshwar Singh, Director (Finance) SJVN Limited, Sh. Ajay Singh, CEO, SJVN Green Energy Limited (SGEL), and Simarpreet Singh, Director, Hartek Group, underscore the collaborative effort to embrace sustainable energy solutions.

Anticipated Impact and Future Sustainability

The Nangal Floating Solar Project is anticipated to generate a staggering 33 million units of energy in its first year, with a cumulative total of 756 million units over the next 25 years. This monumental leap towards sustainability signifies the Hartek Group’s unwavering commitment to shaping a brighter, more sustainable India for generations to come.

Floating Solar and India

At Hartek Group, we’re harnessing the power of water bodies like lakes, reservoirs, and ponds, by not only maximizing solar energy generation but also making efficient use of previously unused surfaces. The cooling effect of water enhances the performance of our solar panels, boosting their efficiency even further. Moreover, by covering water surfaces, our this solutions help combat water evaporation, preserving precious resources for future generations. With India’s vast solar potential estimated at 748 GWp by the National Institute of Solar Energy, our modular floating technology is poised to revolutionise energy access. From mini-grids and off-grid solutions to large-scale projects integrated with the electricity grid, our versatile approach caters to diverse needs, benefiting both urban and rural communities alike.

Deep dive into the history

The concept of floating solar projects in India gained traction in 2014 with the launch of the first pilot project by the National Hydro Power Corporation (NHPC) in Kerala. Since then, the country has witnessed a steady growth in the development of such projects, with several installations across various water bodies, including reservoirs, lakes, and ponds

What’s next in the floating solar projects of India?

These power projects hold immense importance in India’s transition towards sustainable energy. With the country’s growing energy demands and limited land availability, the utilization of water bodies for solar power generation presents a viable solution. It not only helps in reducing land usage but also minimizes water evaporation and enhances the efficiency of solar panels due to the cooling effect of water.

Jumping to conclusion(s)

As a pioneer in the renewable energy sector, the Hartek Group’s Nangal Floating Solar Project exemplifies the potential of floating technology in driving India’s power transition, and sustaining its commitment to decarbonisation and achieving net zero-emission. The project’s success serves as a testament to the group’s vision of leveraging innovation to shape a more sustainable future for the nation.

Stay tuned to ride the wave of change with the Hartek Group!

Frequently Asked Questions

1. What is the Nangal Floating Solar Project?

The Nangal Floating Solar Project is a 22MW solar installation on the Nangal reservoir, aimed at boosting India’s clean energy and reducing carbon emissions.

2. Why are floating solar projects important for India?

Floating solar projects help optimize water bodies for energy generation, reduce land usage, prevent water evaporation, and enhance solar panel efficiency.

3. How much energy will the Nangal Floating Solar Project generate?

It is expected to produce 33 million units in its first year and a total of 756 million units over 25 years, contributing significantly to sustainable energy.

4. What are the benefits of floating solar technology?

Floating solar improves energy efficiency due to water cooling, minimizes water evaporation, and utilizes unused water surfaces for renewable energy generation.

5. What is the future of floating solar projects in India?

With India’s solar potential at 748 GWp, floating technology will play a key role in expanding energy access for both urban and rural communities.